|

Post Installation Inspection Resource #07-500 It’s in the owner’s best interest to know that all pipe in their system has been properly installed and has not been damaged in some way that will threaten the structure of the system or shorten the anticipated design life of the pipeline. Post Installation Inspection provides that proof of proper installation and structural integrity to the owner prior to project closeout or final acceptance. This document highlights some of the basic pipe performance and equipment requirements that should be specified on all pipe installations. Member price: $1.50 Non-member price: $3.00 Order Now |

||

|

Evaluation and Repair Guidelines for New Drainage Pipe Resource # 07-501 All newly-installed pipe installations should require post installation inspection (PII) to determine the condition of the pipe. The following criteria should be applied to all pipe material types and should be utilized to determine the course of action, if any, to be taken when there are cracks, deflections, bulges, creases, tears, spalls, or delaminations in the pipe. The final decision on course of action and acceptability will be determined by the Engineer. Member price: $1.50 Non-member price: $3.00 Order Now |

||

|

Sample Specification for Evaluation of Newly Installed Culvert and Storm Drainage Pipe Resource # 07-502 This Sample Specification for the evaluation of newly installed Culvert and Storm Drainage Pipe has been written in order to provide an example specification for owners to insure national standards are followed and proper evaluation of all types of installed pipe can be accomplished. The most common issues of concern are covers cracks, misalignment, joint openings, buckling, and deflection for newly installed pipe of various materials. Member price: $1.50 Non-member price: $3.00 Order Now |

||

|

Post Installation Inspection Methods, Tools and Reports Resource # 07-503 This document is written to provide the user with a detailed model specification for the Post Installation Inspection of newly installed storm drainage pipe or culverts. National Standards as well as excerpts from several state Department of Transportation’s were utilized in developing this document.With the varying technology available for post installation inspection, it is important to provide some flexibility in the means and methods of carrying out PII as well as the PII report formats. This document aims to outline requirements that will give the owner the necessary information to verify proper pipe installation without confining the contractor to proprietary equipment. Member price: $1.50 Non-member price: $3.00 Order Now |

||

|

Post Installation Evaluation and Repair This document, contains a detailed discussion of the evaluation and repair of newly installed reinforced concrete pipe (RCP). The Matrix and this commentary can be used to provide the evaluation team and the contractor with a reasonable approach to economically evaluate what defects are in need of repair. This document provides descriptions of basic repair methods that can help guide the contractor and/or owner in selecting and reviewing possible repair methods. |

||

|

Video and Laser Measurement Tools Resource #e-017 Our roadway pipe systems are the “unseen” bridges of our nation’s ground transportation systems. While we must address the existing aging system, to maximize the life of future installations we must act now to ensure quality installations are occurring.It is apparent that we must fully address the importance of: • Proper INSPECTION of all installations, • Adequate design life, • Conservative design approaches, • Complete and stringent reviews of all critical construction components, • Strong quality assurance programs throughout the construction process, and • Diligent and proper maintenance of all the components of ou roadway infrastructure. |

||

|

Practical Accuracy of Crack Measurement Resource #e-014 Pipe industry professionals have observed the use of precision measurement technology without a full appreciation of the limitations of the equipment and the human factors involved. This results in inaccurate crack measurements. In general, pipe utility contractors have come to accept and support final inspection results. However, inconsistency and unreliability of field measurements erodes confidence in the inspection process. This, in turn, threatens the future of final inspection and crack measureme approximating crack widths when assessing pipe conditions. For this reason, the pipe inspection and construction engineering communities must fully understand the practical accuracy of using precision crack measurement technology. |

||

|

|

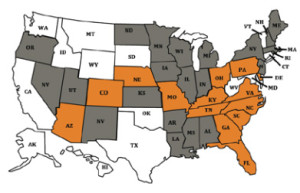

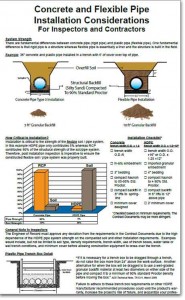

For Owners and Engineer For Inspectors and Contractors |

|

Compaction Equipment and Construction Loads Resource #CPI-06-8/2002 Construction loads are an important but often overlooked factor in pipe design and installation. Even when construction live loads are considered, the loads that result from the compactive effort are often ignored. |

|

Fires in Sewers and Culverts Resource #02-901 The susceptibility of various pipe materials to fires should be considered when planning storm sewer, sanitary sewer or culvert projects. This publication presents laboratory test results performed on various pipe materials in accordance with ANSI/ASTM E84, “Test Methods for Surface Burning Characteristics of Building Materials.” |

|

What Positive Lessons can be Learned from an HDPE Fire? (YSK Bulletin #134) June, 2005 A fire in a 42″ HDPE storm drain turned out to be both frightening and costly to Herriman City, a growing community in Utah. |

|

Concrete Pipe and Box Culvert Installation eBook Apple iTunes (ePUB) Google Play (ePUB) Google Books (PDF) |

|

ASTM D2321 A Few of Your Responsibilities Resource #e-012 It is incumbent upon the product manufacturer, specifier, or project engineer to verify and assure that the pipe specified for an intended application, when installed according to procedures outlined in this practice, will provide a long term, satisfactory performance according to criteria established for that application. |

|

Lessons Learned from the East Texas Fish Hatchery Incident Resource #e-011 In April 2009, inspectors at the John D. Parker East Texas Fish Hatchery discovered that sections of high-density polyethylene (HDPE) drainage pipes had collapsed. In a Compromise and Settlement Agreement HDR Engineering, Allco, and Travelers Casualty and Surety Co. of America, the Engineer paid $3.18 million to TPWD and $213,000 to the Contractor. It is noteworthy that the HDPE pipe manufacturer was not a party to the Settlement. |

|

Installation Anomalies? You Be the Judge (YSK Bulletin #121) August, 2002 HDPE pipe is installation sensitive, and the HDPE pipe industry has not educated engineers and contractors with regards to proper installation of their products. However, improper installation is not the only problem. These case studies have been touted by the HDPE industry as quality installations. Check it out and “you be the judge.” You might be surprised with what you find! |