– Editorial – Industry Issue –

Concrete Pipe Week Strengthens in 2017

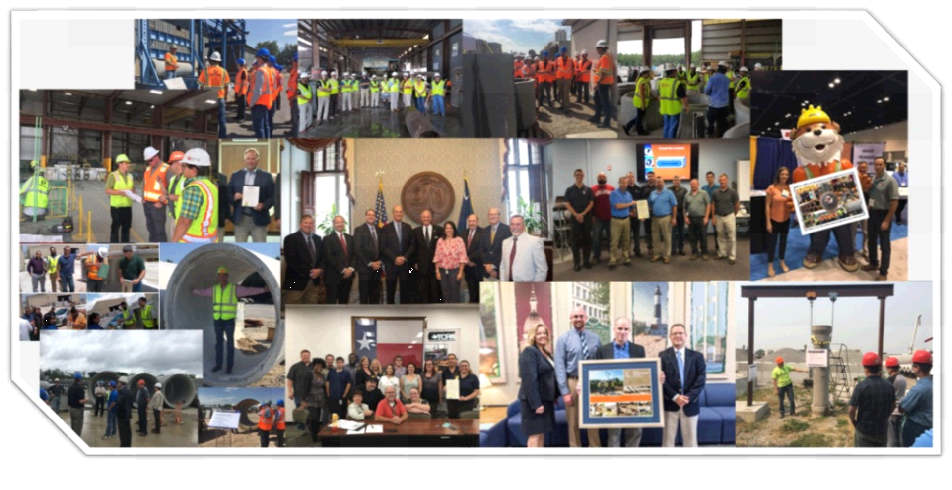

Proclamations recognizing Concrete Pipe Week were signed by the offices of governors, senators, and mayors in 32 states representing 76% of the population of the United States of America.

Statistics for Concrete Pipe Week 2017, and the popularity of plant tours, education, and training events (held concurrently with Concrete Pipe Week), prove that the American Concrete Pipe Association and its members continue to build trusting relationships with state governors, senators, mayors, regulators, and specifiers. The national event helps build awareness of corporate brands and the brand of concrete pipe and precast boxes used for drainage pipeline systems and culverts. Local events included training days, plant tours, governor meetings/photo ops, a “Total Eclipse of the Pipe” event, State Senate Chamber presentations, and U.S. Congressman tours. Many events are posted on social media sites of members (Facebook, LinkedIn, and YouTube), and the Facebook site of the ACPA.

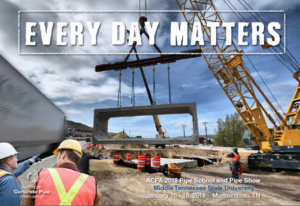

The 2017 Concrete Pipe Week Poster represents the importance that our federal and state legislators place on the significance of dependable infrastructure, constructed with reinforced concrete pipe and precast products. The value of the industry to the nation’s economic well-being, and the substantial contribution of individuals in our industry to the health, safety, welfare, and quality of life cannot be overstated.

Reinforced concrete pipelines and precast boxes and pipe culverts celebrated during Concrete Pipe Week, create an “Accelerated Precast Construction (APC)” culture that fits tightly into FHWA’s “Every Day Counts” initiative. “Every Day Counts is not about inventing the next big thing. It’s about taking effective, proven and market-ready technologies and getting them into widespread use.” (FHWA). APC reduces road user impacts, costs, construction time and weather-related time delays. APC improves work zone safety not only for the road user, but for the on-site construction worker, too. APC minimizes impacts on our environment and existing roadway alignments.

Concrete Pipe Week 2017 set the context for Pipe School and Pipe Show 2018, January 15-18 in Murfreesboro, Tennessee, where the theme of Every Day Counts celebrated during Concrete Pipe Week, continues. Guest speaker, Bob Chapman will speak about Everybody Matters. In the concrete pipe industry, Everybody Matters and Every Day Matters, and the program for Pipe School/Pipe Show reflects that theme.

Each year Concrete Pipe Week reminds regulators, specifiers, design engineers, contractors, elected representatives and the public about the importance of the precast concrete pipe industry to America. In August, 2018, Concrete Pipe Week will once again cast a spotlight on an industry that helps build America’s critical infrastructure.

– Article – Industry Issue –

A Burning Issue

By: Branimir Kovac, Thompson Pipe Group

|

By: Branimir Kovac, Thompson Pipe Group Under normal conditions, wildfires are nature’s way of facilitating forest rejuvenation by burning off dead wood and brush and clearing the way for new growth. People, however can cause wildfires, deliberately or by accident. In the last few years, there have been massive wildfires destroying critical infrastructure and entire communities in many regions of the USA. What happens to pipelines that are buried under roads during a wildfire? If buried close to the surface, or open like a culvert, high density polyethylene (HDPE) and polypropylene (PP) may be damaged or destroyed. Fires have little or no effect on the structural strength, flow capacity, corrosion, and abrasion of a concrete sewer or culvert. The repair or replacement of infrastructure is incredibly expensive, and there are social ramifications, such as the interruption of service and the disruption of traffic, if the damaged line runs near a road. Pipe culvert failure can block emergency service vehicle access, and this can result in the loss of property and affect lives. Fires in drainage pipes are not uncommon. The American Concrete Pipe Association has dozens of articles with sources about the danger and effect of fire in drainage systems. |

– Article – Industry Issue –

Canadian Concrete Pipe & Precast Association Publishes Environmental Product Declaration (EPD) for Concrete Pipe, Box Structures & Manholes/Catch Basins

– Article – Concrete Pipe and Precast Box/Manhole Technology –

Cracks and Autogenous Healing

What is an acceptable level of cracking in concrete? There’s no easy answer, since different civil engineering disciplines each have their own design criteria. Concrete sub-structures typically have more tolerance to cracking than concrete bridges and buildings which are more exposed to weathering from the natural elements. Based on the American Association of State Highways and Transportation Officials’ (AASHTO) Post Installation Guidelines for Underground Concrete Pipe (a key reference for many municipal specifications), the following crack criteria is used:

What is an acceptable level of cracking in concrete? There’s no easy answer, since different civil engineering disciplines each have their own design criteria. Concrete sub-structures typically have more tolerance to cracking than concrete bridges and buildings which are more exposed to weathering from the natural elements. Based on the American Association of State Highways and Transportation Officials’ (AASHTO) Post Installation Guidelines for Underground Concrete Pipe (a key reference for many municipal specifications), the following crack criteria is used:

- Longitudinal crack width < .05”. Considered minor and not a cause for remediation.

- Longitudinal crack width greater than .05” but less than .10”. In areas where soil and runoff pH > 5.5, not a cause for remediation.

- Longitudinal crack width > .10”. Remediate or replace the pipe.

Inland Pipe published a brochure called “Cracks & Autogenous Healing.” Download a copy.

In August, 2017, concrete pipe producers and Mountain States Concrete Pipe Association demonstrated autogenous healing and showed the results on video. Concrete pipe has the ability to heal itself. In the presence of moisture, concrete extrudes calcium hydroxide, which upon exposure to the atmosphere, is converted to calcium carbonate (limestone) which seals the crack.

In August, 2017, concrete pipe producers and Mountain States Concrete Pipe Association demonstrated autogenous healing and showed the results on video. Concrete pipe has the ability to heal itself. In the presence of moisture, concrete extrudes calcium hydroxide, which upon exposure to the atmosphere, is converted to calcium carbonate (limestone) which seals the crack.

In the demonstration, a concrete pipe was overloaded and cracked to 0.15 inches–well beyond an acceptable crack in the field. The pipe was then cut in half. The bottoms of the two sections were sealed and then one half was filled with water and left to stand for a month. The second was filled with water in the morning of the comparison between the two halves. After resting for a month filled with water, the first half of the pipe had begun to heal itself and was leaking water at a rate of 1/2 inch per hour. The second half which had not had time to heal released water at a rate of 1/2 inch per minute. What a difference! Same pipe, same crack, huge difference.

Watch the video to see the difference. In the photo, the pipe section on the left was filled with water for a month and shows signs of autogenous healing. In the video, the demonstration was recorded on the opposite side of the photo, and it is the pipe on the right that is undergoing autogenous healing.

ACPA Resources

CP Info: Cracks in Installed Reinforced Concrete Pipe

ePipe: What is the Practical Accuracy of Crack Measurement in Concrete Pipes?

Brochure: Post Installation Evaluation and Repair of Installed Reinforced Concrete Pipe

– Article – Concrete Pipe and Precast Box/Manhole Technology –

Supporting the Load

By: Branimir Kovac, Thompson Pipe Group

Without concrete, our cities would be unremarkable, highway traffic would move slowly, and bridges would have very short lengths. Without concrete pipe, we wouldn’t have ready access to clean drinking water, or safe, timely, disposal of stormwater or sanitary sewage.

Without concrete, our cities would be unremarkable, highway traffic would move slowly, and bridges would have very short lengths. Without concrete pipe, we wouldn’t have ready access to clean drinking water, or safe, timely, disposal of stormwater or sanitary sewage.

Egyptians used a primitive form of concrete when building the pyramids. In 300 BCE, the Romans used a more advanced concrete in their buildings, several of which still exist today. The Romans learned how to make concrete that sets underwater, and used it in the construction of viaducts and more.

Portland cement was developed in the 19th century and is used today as the binder in concrete. Reinforced concrete was introduced in France in the middle of the 19th century, and in 1903, in Cincinnati, a skyscraper was built with twisted steel-bar reinforcing. In 1910, a viaduct built by the Delaware, Lackawanna and Western Railroad became the largest reinforced concrete structure in the world at that time.

The oldest known concrete sanitary sewer in the U.S., a 6-inch diameter pipeline, that may still be functioning today, was installed in 1842 in Mohawk, New York.

Compressive strength of concrete, and the tensile strength of reinforcing steel, enables reinforced concrete to withstand heavy loads. Flexible thermoplastic and corrugated metal conduit functions as a liner that conveys a fluid. The overall structural strength to withstand loads is created by carefully constructing the soil envelope that surrounds the conduit. RCP, however, arrives on site as a structure, predesigned to withstand the anticipated load.

It is the responsibility of the design engineer to select the appropriate drainage product, and the responsibility of the installer to create the strength of the overall installation. When installing RCP, the embedment material is not as critical as it is for thermoplastic or corrugated metal conduit. RCP is designed to support as much as 90% of both dead and live loads after production at the plant.

If the mistake is made comparing pipe material costs of a length of RCP with the same length of thermoplastic or corrugated metal conduit, pipe material costs of the flexible products may be less costly than RCP. But, when the cost of installation is added within the context of life cycle cost analysis, a concrete pipeline installation has greater asset value. Functioning concrete pipelines and culverts that were installed decades ago are monuments to the strength and longevity of RCP.

See Branimir’s complete article.

– Article – Stormwater Pipeline Systems –

Precast Concrete Drainage Components Used for Phoenixville’s New School Stormwater Management System

By: Barbara Bogo, Oldcastle Precast

Oldcastle Precast supplied over 11,000-feet Class III reinforced concrete pipe, along with multiple precast concrete stormwater drainage and sanitary structures for Phoenixville Area School District’s new 152,000-square-foot school and early learning center’s stormwater management system in Phoenixville, Pa. The system incorporates stormwater management facilities based on PADEP Stormwater Best Management Practices, that accommodate both Pensylvannia Department of Environmental Protection (PADEP) / Crawford County Conservation District (CCCD) requirements as well as Schuylkill Township storm water ordinance requirements. Precast components were used to form the stormwater management systems for the new Manavon Elementary School and the Phoenixville Area Early Learning Center.

Oldcastle Precast supplied over 11,000-feet Class III reinforced concrete pipe, along with multiple precast concrete stormwater drainage and sanitary structures for Phoenixville Area School District’s new 152,000-square-foot school and early learning center’s stormwater management system in Phoenixville, Pa. The system incorporates stormwater management facilities based on PADEP Stormwater Best Management Practices, that accommodate both Pensylvannia Department of Environmental Protection (PADEP) / Crawford County Conservation District (CCCD) requirements as well as Schuylkill Township storm water ordinance requirements. Precast components were used to form the stormwater management systems for the new Manavon Elementary School and the Phoenixville Area Early Learning Center.

Oldcastle Precast manufactured and shipped 8,992 feet of precast concrete RCP pipe (ranging from 14-inch to 66-inch diameter) produced at their Croydon, Pa. and Folsom N.J. facilities, while the Telford and Easton, Pa. facilities manufactured the pipe junction boxes, pipe headwalls, numerous catch basin inlets and manholes.

The precast components, in addition to an on-site storm water infiltration system and new stormwater basins, constitute the stormwater management system for the new elementary school and the early learning center.

Since a functioning stormwater infrastructure is critical to support the movement of goods, people, and services on state highways and roads, the Pennsylvania Department of Transportation (PADOT) additionally required highway improvements at West Pothouse Road and Meadow Brook Lane previous to the new school opening in 2017.

As a part of the roadway improvements, PADOT required contributory stormwater management systems to accommodate increased roadway stormwater runoff from the new facility. This portion of the project required Oldcastle Precast to produce an additional 2,322-feet of RCP pipe, 14-inch to 23-inch elliptical pipe and 18-inch to 48-inch diameter round pipe, catch basin inlets with bike safe grates, headwalls and manholes.

– Article – Concrete Pipe and Box Culverts –

County Materials Aids in Emergency Repairs After Hurricane Hits Florida – Contractor Wins an Award in 2017

By: County Materials Corporation

Heavy rain pounded most of Florida when Hurricane Hermine made landfall on September 2, 2016. The hurricane left nearly $550 million in damages across the state, including a washed-out portion of State Road 72, about 10 miles east of Sarasota. When the Florida Department of Transportation (FDOT) arrived, they found gaping holes in the road’s surface, forcing FDOT to close the road. Finding a contractor who could repair the road quickly was a priority because it is a major arterial road. With no detours, motorists were forced to drive ten miles to an alternate highway.

Florida Safety Contractors was selected for the job with the expectation they would finish in one week. FDOT offered an incentive bonus to the contractor, if the job could be finished in less than 5 days. When crews arrived on site, they saw that much of the soil surrounding the culvert had washed away, causing the weight of the road to crush the corrugated steel pipeline. To prevent another road collapse in the swampy area, Florida Safety Contractors chose reinforced concrete pipe (RCP) manufactured by County Materials in Astatula, FL.

Construction began by removing the soil and damaged metal pipeline to prepare for a new culvert. The job required 18 units of 60-inch diameter Class III RCP, for two 80-foot rows. Once the pipe was installed, the contractor used a flowable fill to embed the pipe. Poured concrete provided additional support for the structure to prevent a future washout. Headwalls were added for even more strength. After the concrete cured, the road was repaved, and the job completed.

Florida Safety Contractors met the requirement for the incentive bonus. County Materials played a vital role in ensuring the contractor succeeded by delivering pipe on an as needed basis. Units were delivered at all times of the day and night, ensuring that construction never stopped. Nearly a year after the emergency repair, the Florida Transportation Builders’ Association (FTBA) recognized Florida Safety Contractors with a ‘Special Significance’ award on August 12 in Amelia Island. FTBA, presented Florida Safety Contractors with the award for their expedience in completing the project with little lead time, and allowing reopening of the road before anybody thought possible.

– Article – Concrete Pipe and Box Culverts –

Applications for Precast Concrete Box Sections

Concrete Pipeline Systems Association

Precast concrete boxes are ideal for a range of applications, although their traditional use is for diverting watercourses. The versatility of these structures sees them increasingly used for retention and detention systems, pedestrian underpasses, access shafts, service tunnels, sea outfalls, road crossings and other applications.

Precast concrete boxes are ideal for a range of applications, although their traditional use is for diverting watercourses. The versatility of these structures sees them increasingly used for retention and detention systems, pedestrian underpasses, access shafts, service tunnels, sea outfalls, road crossings and other applications.

Proven strength and performance means long service life. Unlike structures manufactured from steel, precast concrete culverts do not require additional treatment. They do not rust, and the smooth internal finish of the concrete ensures optimum flow of water.

Culverting watercourses and channels is one of the most common uses of precast boxes enabling development of land crossed by watercourses. Openings for access and pipe entry can be incorporated during manufacture, and smaller diameter holes can core drilled during installation. Channels can be provided with or without removable lids, enabling applications from open water course diversion, to service ducts for pipes and cables.

Single or multiple runs of precast boxes provide the most economical in-line or offline storage of storm water. These can be located under car parks, grassed areas or under roads following the line of the roadway. Precast boxes can be supplied with end walls, access and pipe entry openings, and are designed to carry the traffic loads or any other surcharge determined by the location. Rectangular box sections laid side by side, with a nominal gap to allow for relative movement, provide the largest flow capacity in the minimum space.

Precast box drainage and collection systems can be designed for minimum allowable cover and for no side pressure relief from the ground. They are a perfect replacement for standard pipes maximising the available flow area.

Fire protection with concrete is ideal for rapid and safe underground escape from industrial and commercial premises, car parks, shopping centres and sports arenas. In addition, precast box systems can accommodate underground services.

Specially designed box structures with increased cover to reinforcement and effective crack control provide the durability to resist the most extreme conditions and are ideal for shafts.

– Blogs and Social Media –

Commentary on ACPA’s 2017 Media Survey

A video blog (vlog) by Grant Lee, American Concrete Pipe Association

Valuable insight into how people in North America’s concrete pipe industry receive information was gained through a survey of Concrete Pipe News in July, 2017.

The survey suggests that 50% will spend approximately 90 seconds reading about an industry issue or application of pipe and precast boxes, and look at one photo. Approximately 1/3 of readers spend up to 10 minutes reading an article that has 3 photos. What does this mean to ACPA and its members who view the ACPA as a trusted source of technical and industry knowledge?

The survey confirms that producer members who are posting articles about plant tours and projects on their Facebook pages are doing so in a way that will be opened, seen, and read by followers of the page. Over the past few years, there has been a shift in reading habits to a preference for short, information or knowledge-rich blogs with only a few photos with plenty of exciting content that enhances the copy.

There is a significant number of readers who suggest a preference for longer articles with a few photos that take 10 minutes or less to read. About a third of CP News readers will read blogs of 500 to 1,000 words. Although CP News would accommodate such lengths, the preference is 500 words with three photos. Articles longer than 500 words could be placed on LinkedIn personal or company pages with a single photo or image that helps describe the focus of the article.

The survey revealed some insight into the nature of articles preferred by readers. These include technical, industry issues and new products. It is assumed that when readers are looking for something new, they may also mean new application and new research about products.

And, the survey reflects information from the net suggesting professionals tend to look to LinkedIn, Facebook and YouTube for information. This observation is supported by metrics of ACPA’s social media sites that indicate most social media traffic is on Facebook, LinkedIn and Youtube.

Look for short, information/knowledge-rich articles in CP News with links to longer articles or sites where readers can spend more time searching for knowledge sources that can be trusted. An added feature to CP News are these audio and video broadcasts by ACPA staff and representatives of member companies. Concrete Pipe News embraces change to facilitate online communications between readers and bloggers.

– ACPA SPONSORS –

– Pipe School and Pipe Show EVERYBODY MATTERS –

In the concrete pipe industry, Every Day Matters. FHWA launched Every Day Counts to build a better America, quickly. Register to attend the 2018 Pipe School and Pipe Show for training and education to improve services nationwide. While there, learn a new way of leadership through Bob Chapman’s business success described in Everybody Matters.

Click here for more information and to register!

– Don’t wait ’til the last minute – Apply now –

The purpose of ACPA’s Project Achievement Award is to recognize agencies which have demonstrated creative and innovative accomplishments through projects that have been constructed with precast concrete pipe or boxes. In addition, the award raises public awareness of the activities and contributions of public agencies, the American Concrete Pipe Association, and its members.

The purpose of ACPA’s Project Achievement Award is to recognize agencies which have demonstrated creative and innovative accomplishments through projects that have been constructed with precast concrete pipe or boxes. In addition, the award raises public awareness of the activities and contributions of public agencies, the American Concrete Pipe Association, and its members.

To compete for the award, any member agency of AASHTO may apply. Agencies and ACPA members may submit projects jointly or separately. ACPA members submitting projects separately must obtain the signature of the responsible agency on their entry form.

Application packets/entry forms are due March 1, 2018.

Members are beginning to prepare applications for the Project Achievement Award. If you need help, contact Grant Lee at glee@concretepipe.org.