As the 20th anniversary of a significant canal breach in Utah passed, the canal company’s investment in repairs and replacement are a triumph for the water users and the engineering community. Precast concrete products have been integral to the improvements.

On July 11, 1999, the Davis and Weber Canal breached. Nearby Riverdale City homes faced the brunt of the flood, as muddy water and silt forced hundreds of residents to evacuate. Fortunately, no lives were lost, yet the deluge damaged more than 70 houses and caused the need for canal repairs that would ultimately cost upwards of $10 million.

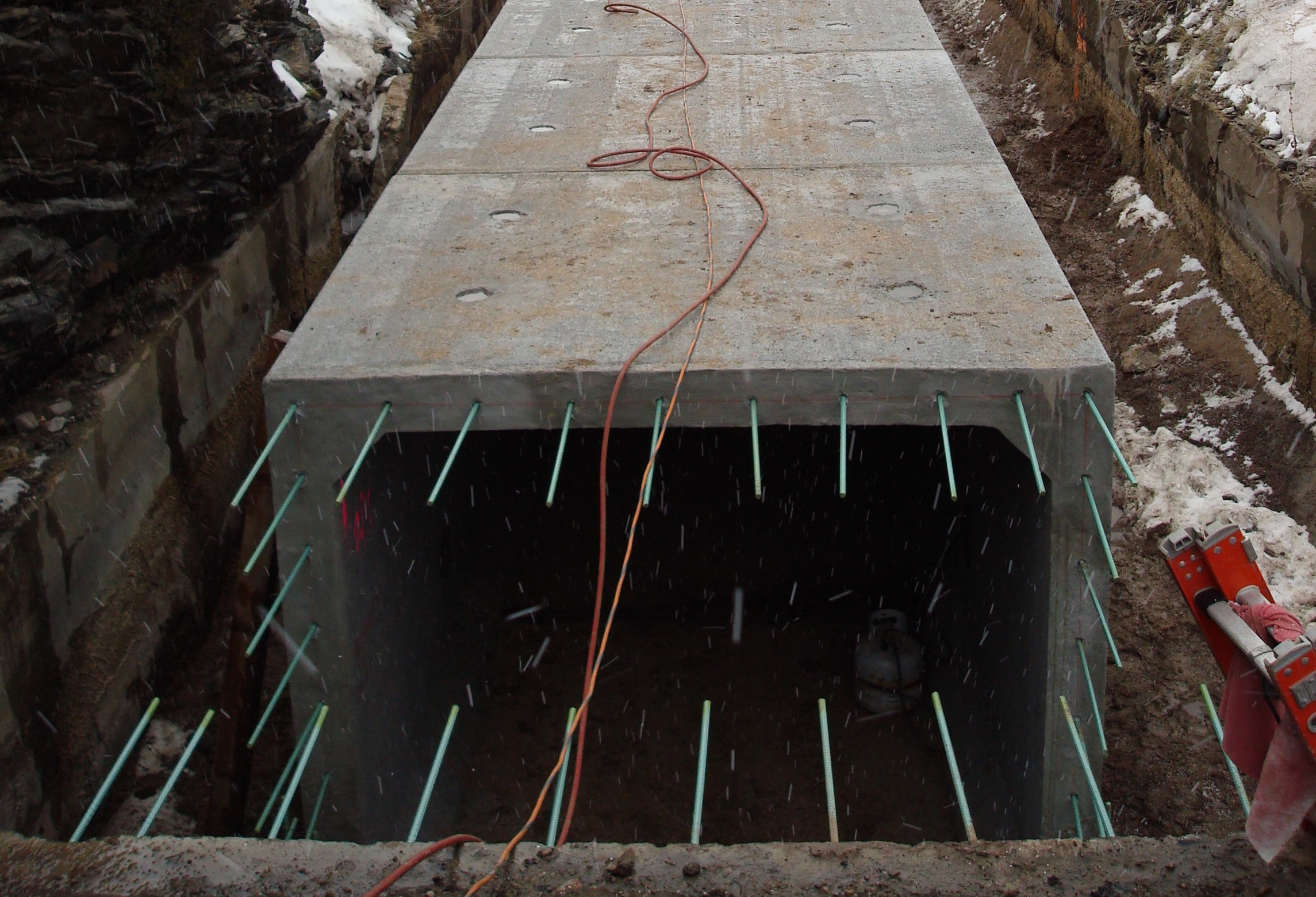

Now, 20 years later, critical sections of the canal have been replaced through company funds, extensive state loans and federal grant funding. Due to its benefits including strength, durability and resiliency, reinforced precast concrete box culvert (RCB) was used in several locations as the canal has been replaced and enclosed.

Century of History

The original, earthen Davis and Weber Counties Canal dates to the mid 1880s when it was constructed to carry water to the early settlement farmlands in Weber and Davis Counties. Ranging in widths from 10 to 20 feet, the rough and uneven canal was reconstructed by 1911 and lined with concrete. Workers placed tightly rolled wool rope material in the concrete joints to allow for the concrete’s expansion and contraction. However, by 1915, the joints began to leak due to the wool’s deterioration. Over the years, the canal underwent numerous repairs until today, when more than half the canal system has been replaced with cast-in-place box culvert, precast box culvert, large concrete pipes or concrete trapezoidal liner with water stop.

Post-Breach Repairs

The Davis and Weber Counties Canal Company (DWCCC) had J-U-B Engineers of Kaysville, Utah, which had worked for the canal company since the late 1980s, design the repairs through the breach. J-U-B also prepared and executed initially a long-term plan for the design and construction of improvements for the upper 9 miles of the 17.2-mile-long canal. Now there is a complete improvement plan for the entire canal system, updated by a Bureau of Reclamation System Optimization Review grant.

In addition to the breach, the improvements included replacing the most critical areas of the canal. The capital improvements solved several issues, including: leakage, vegetation growth, evaporation, algae growth, etc. Leakage was estimated at nearly 30 percent in the upper section of the canal. Watertight joints have greatly reduced this leakage and saved roughly 30 percent, which means additional water for the end users.

To obtain funding, DWCCC was able to secure State of Utah, Board of Water Resources loans to make improvements and continues to pay off such indebtedness. The company was also successful in receiving ARRA federal grants and Bureau of Reclamation WaterSMART grant monies, which still require a minimum of 50 percent match. To date, more than $39 million of improvements have been completed on the overall canal system.

“Reinforced concrete box culvert was used in much of the canal, as it provided a structure that fit the profile of the canal and protected the canal against landslides. It also provided a closed conduit that provided better more secure water conveyance,” says Bryce Wilcox, J-U-B Engineers.

In several places, the canal was enclosed by going to reinforced concrete box culverts to avoid rock or debris slides, eliminate airborne debris entering the canal, and to improve safety. RCB was chosen for its strength, longevity and constructability.

Local precast concrete suppliers worked closely with J-U-B to assist with design, alignments and constructability. Careful coordination and strong relationships among members of the project team have facilitated a positive outcome.

“The Canal Company is pleased with all of the canal system improvements by maintaining a historical water conveyance system to the community as it transitions from agriculture to residential,” says Rick Smith, General Manager, DWCCC. “Water is necessary to maintain the quality of life.”

Project Team

Engineer of Record: J-U-B Engineers, Inc.

Contractors: Bowen Construction, Whitaker Construction, Reynolds Excavation, Flare Construction, Gerber Construction

Precast Supplier: Oldcastle Infrastructure, Geneva Pipe and Precast

Funding: State of Utah/Board of Water Resources, Bureau of Reclamation (WaterSMART)