– Editorial – Industry Issue –

Concrete Pipe – Responsible Specifications Today Deliver Reliable Infrastructure Tomorrow

By: Russell Tripp, American Concrete Pipe

Welcome to the 2018 Winter edition of the Concrete Pipe News. This editorial’s focus is on responsible specifications and your choice as design engineers and agencies. I hope you find this information useful in your quest for delivering reliable infrastructure tomorrow.

The U.S. has sustained 219 weather and climate disasters since 1980 where overall damages/costs reached or exceeded $1 billion (including consumer price index adjustment to 2017). The total cost of these 219 events exceeds $1.5 trillion. This total now includes the initial cost estimates for Hurricanes Harvey, Irma, and Maria. During 2017, the U.S. was impacted by 16 separate billion-dollar disaster events; a historic year of weather and climate disasters. (https://www.ncdc.noaa.gov/billions/)

Following the disaster events, news reports documented pipeline systems and culverts that were irreparably damaged. Most reports identified the damaged or destroyed underground infrastructure as thermoplastic systems or corrugated metal from the wild fires in California to the hurricane damage in Texas and Florida.

Designers of pipeline systems and culverts have choices of when to specify structural concrete pipes, flexible thermoplastic conduits, or corrugated metal conduits. When all factors are considered, such as total installation costs, total life-cycle costs, site conditions, structural bedding/embedment materials, hydrostatic pressures, and other local conditions, as well as hazards caused by nature and humankind, reinforced concrete pipe and reinforced concrete boxes are the clear choice. Further, where the threat is obvious to health and safety and the economy of an entire region or city through critical buried infrastructure, why would anything other than concrete pipe and precast boxes be specified? The choice, of course, is yours. And we support keeping it in your hands. While I admit my bias to concrete products, proper installation according to manufacturer and agency guidelines, followed by proper post installation inspection and the factors referenced above, are the key to delivering reliable infrastructure today and tomorrow.

America is well along the road to building and rebuilding its infrastructure with a goal of resilient cities. Many disaster plans are in place and many more being completed. Cities that are prepared with resilient infrastructure can withstand or recover quickly from disastrous events.

ACPA broadcast this message of resiliency to its members and followers on social media in January, as a video dubbed, “Disaster proof your culvert!” The video captures the worst that can happen to critical infrastructure. It is a 30-second video that spotlights the durability of concrete pipe. The video is archived on ACPA’s social media sites as a GIF or wmv file. Reinforced Concrete Pipe…It is rugged, rigid, and resilient.

I welcome your feedback! Until next time.

– Article – Concrete Pipe and Box Culvert –

Failed 16-year HDPE Flood Control System Replaced by RCP

By: John W. Washabaugh, Northern Concrete Pipe, Inc.

– Article –Concrete Pipe and Box Culverts –

Precast Box Culvert Replaces Aging Steel Beam Bridge

By: William C. Adams, Hancock concrete Products LLC

Double-drop deck trailer used to transport 24-foot wide x 10-foot high box section. Precast box sections installed within 2 days of a 7-day installation. Precast box sections installed within 2 days of a 7-day installation.  Inset shows completed structure before restoring the creek flow and completing the culvert installation. Inset shows completed structure before restoring the creek flow and completing the culvert installation. |

A steel beam bridge constructed in 1962 on County Road C-38 in Johnson Township, near LeMars Iowa required replacement because construction of a new ethanol plant in Plymouth County contributed to approximately 1,000 cars a day on County Road 38. Tom Rohe P.E. – County Engineer – made the decision to replace the bridge with a single cell culvert comprised of 24-foot x 10-foot precast boxes and precast end sections.

There are situations where replacing a failing bridge, or bridge structure that is approaching the end of its design life with a precast concrete culvert, is a choice that makes good engineering sense. Some considerations in choosing precast over an alternate construction option include: the hydraulic characteristics of the watercourse; hydraulic design standards; hydrological considerations; complexity of design; availability of materials; and, speed of installation. This impacts local commerce and community dependant upon an open roadway, and maintenance of the culvert. Benefits of specifying precast concrete boxes for bridge structures are many:

The cost-effective advantages of precast box production and construction methods are available in products manufactured in accordance ASTM C1577 – 17, Standard Specification for Precast Reinforced Concrete Monolithic Box Sections for Culverts, Storm Drains, and Sewers Designed According to AASHTO LRFD, the standard specification used to replace the 43-foot x 28- foot bridge. Installation of box sections began on September 13. All were installed within two days of a 7-day installation period. The culvert is the largest single-cell culvert in Iowa. References: Construction Replacement or Alteration of Bridges and Culverts |

– Article – Concrete Pipe and Box Culverts –

Precast Concrete Stormwater Detention System for New School

By: Barbara Bogo, Oldcastle Precast

Portion of Storm Sewer Constructed in 1884 Replaced with Precast Concrete Boxes

By: Riley Dvorak, Forterra, Maple Grove, MN

|

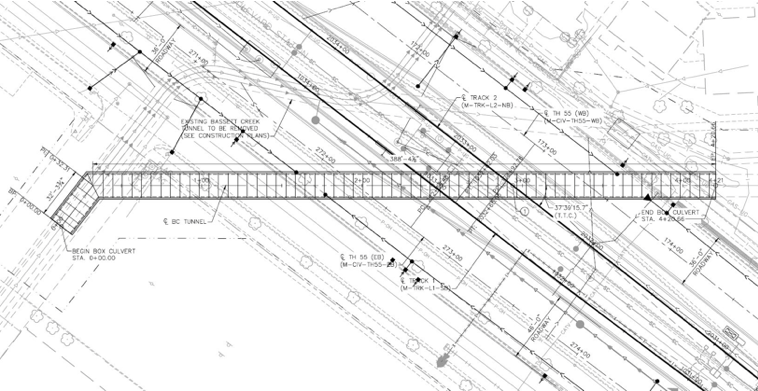

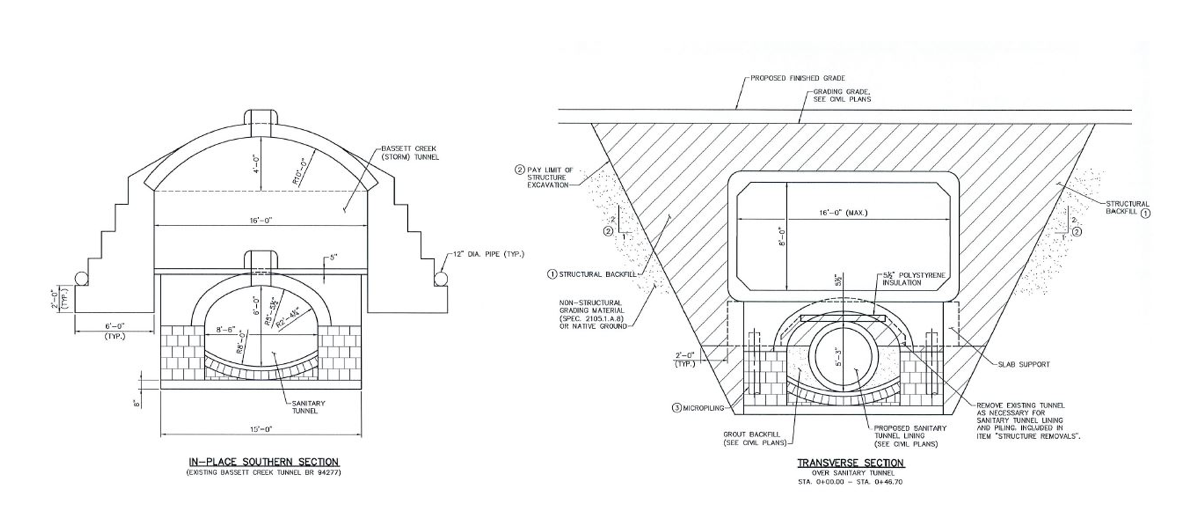

Plan view of new precast box layout.

Sketch showing Bassett Creek storm sewer over sanitary sewer and design of the box storm sewer. Installation of box culvert on alignment on top of FRP sanitary sewer. |

Precast concrete boxes are being used to realign a section of the Bassett Creek storm sewer tunnel under Highway 55 in Minneapolis. Some existing portions of the section being replaced are up to 133 years old. The original configuration of the system consisted of a large, brick-and-mortar storm tunnel with a separate sanitary line running directly underneath. The existing sanitary sewer will be re-lined with a slightly smaller fibre reinforced plastic (FRP) conduit placed inside of the original sanitary line and the annular space then filled with grout. The old storm tunnel will be removed, and a precast culvert will realign the storm flows through a new, offset configuration underneath Highway 55. The realigned tunnel extends 420 feet and begins with a few 16-foot x 8-foot precast sections to match the existing sewer dimensions. The remainder of the line is comprised of 14-foot x 8-foot sections that reconnect to a newer, existing box on the other side of the highway. The project utilizes 70 pieces of reinforced concrete box sections manufactured by Forterra, a local precast company. The layout includes precast bends and transition pieces, as well as cast-in openings for storm laterals and access holes.

The first of two phases of installation were completed in December 2017 with over 350 feet of the new box already installed under Highway 55. The second phase will be completed in spring, 2018. The storm sewer line is being relocated to accommodate the new Van White Station and LRT tracks in the median. Besides being constructed to support the new light rail, the tunnel replacement under Highway 55 is required because the Minnesota Department of Transportation considers the older sections of the sewer to be structurally deficient. The relocation needed to be completed during a low-flow time for storm water, which is historically during the fall and winter. Construction of the Bassett Creek Tunnel began when city planners wanted to build where the creek passed through downtown Minneapolis to the Mississippi River. A new tunnel was built to carry Bassett Creek to the Mississippi, and the original tunnel now carries stormwater from a much smaller area. References: Tracking the Blue-Line Extension |

Pipe School/Pipe Show 2018 Highlights

| Exhibitors/Sponsors

Advanced Concrete Technologies Inc.

|

In an industry that is all about building resilient infrastructure, the resiliency of ACPA staff and faculty of Middle Tennessee State University were tested on Day 1 of Pipe School/Pipe Show 2018. A severe winter storm struck Murfreesboro and MTSU cancelled classes and closed its doors. What to do?

As the theme of Pipe Show states, “Every Day Matters.” The ACPA Team pulled together immediately, no matter their role at Pipe School, and worked with Dr. Brown of MTSU to improvise, adapt and overcome the potential of a cancelled event. The schedule of Pipe School was improvised, as was the location of various classes. Many of the 443 delegates, including 47 DOT representatives from across the Nation, expresses appreciation for the quality of the classes and training. Highlights

The 2019 Pipe School/Pipe Show will return to the Lone Star State.

|

Commentary on 2017 Socmed Trends and ACPA Comparison

By: Grant Lee, CPM, American Concrete Pipe Association

| NTH Consultants, Ltd., Northville, MI, December 27, 2017

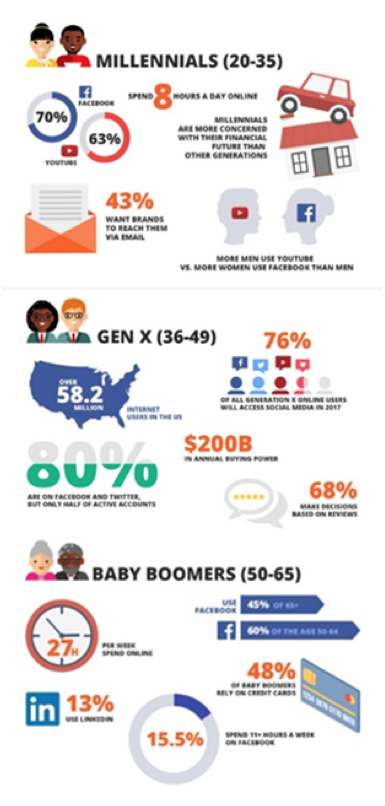

References: Surprising Stats on Every Generation’s Social Media Habits (Infographic) |

ACPA’s most active social media (SOCMED) site is Facebook. This is followed by its LinkedIn Group site called “Pipelines and Pipe & Box Culverts.” ACPA has a LinkedIn Company page, Twitter account at “ConcretePipeUS,” a YouTube Channel (AmericanConcretePipe), and a Pinterest account. All sites are designed to message specific audiences based on the three main generations active in the North American concrete pipe industry. This marketing tactic was set in place to help ACPA achieve its mandate, “to increase concrete pipe market share (2017 strategic plan).

A 2017 article, “Surprising Stats on Every Generation’s Social Media Habits (Infographic) looks at marketing specific generations to benefit your business. That article combined with recent stats on Linked helps measure the effectiveness of the ACPA social media sites with modern trends. Successful marketing strategies must include tactics based on socmed networks, because 78% of the U.S. population has social network profiles and more than 90% of brands use two or more social networks. By the numbers By October 2016, there were 60 million Facebook business pages. ACPA’s business page has 979 likes and 973 followers. When someone likes ACPA’s page, the default setting is that they also follow the page. When someone follows the page, posts will appear on their personal Facebook feed. Six people who like the page have elected to not receive posts. This is a strong endorsement of the quality of content of ACPA’s page. ACPA’s LinkedIn group page, “Pipelines and Pipe & Box Culverts,” has 887 members. It shares articles and asks questions about pipelines and culverts. Created in June 2017, ACPA’s company page has 160 followers. A company page helps people know your business or organization better through news releases, industry news and issues, public awareness, and links to blog posts. ACPA’s Twitter account at “ConcretePipeUS,” has 358 followers. Data suggest that 79% of accounts are outside of the USA and that the number of tweets per minute is declining. During January 2018, ACPA’s account generated 2,692 impressions. ACPA’s followers are obviously interested in ACPA tweets. ACPA’s YouTube Channel has 34 followers. As of April 2015, only 9% of U.S. small businesses use YouTube. Pinterest was set up to display interesting and unique photos of concrete pipe and boxes. 2/3 of pins represent brands and products, and the average time spent per visit is 14.2 minutes. 81% of the users are women but note that 76% of women use Facebook compared to 66% of all men. By generation It is important to place socmed activity information against a background of the generations using the sites to enable an assessment of interaction with ACPA’s wide array of audiences. Millennials (GenY), aged 25 to 35 spend 8 hours a day online. 70% are on Facebook and 63% on YouTube. 76% of Gen X (36-49) use Facebook, Twitter, YouTube, and Instagram, but, only half of the 80% on Facebook and Twitter have active accounts. Baby Boomers, aged 50-71 spend 27 hours a week online. 13% use LinkedIn and 45% over 65 use Facebook. 60% between 50 and 64 use Facebook. 15.5% of Boomers spend more than 11 hours a week on Facebook. ACPA has set up a socmed network to touch all generations active in the concrete pipe industry. Content is released where it is expected to have the greatest return on time spent to help increase concrete pipe market share. |

– Don’t wait ’til the last minute – Apply now –

The purpose of ACPA’s Project Achievement Award is to recognize agencies which have demonstrated creative and innovative accomplishments through projects that have been constructed with precast concrete pipe or boxes. In addition, the award raises public awareness of the activities and contributions of public agencies, the American Concrete Pipe Association, and its members.

The purpose of ACPA’s Project Achievement Award is to recognize agencies which have demonstrated creative and innovative accomplishments through projects that have been constructed with precast concrete pipe or boxes. In addition, the award raises public awareness of the activities and contributions of public agencies, the American Concrete Pipe Association, and its members.

To compete for the award, any member agency of AASHTO may apply. Agencies and ACPA members may submit projects jointly or separately. ACPA members submitting projects separately must obtain the signature of the responsible agency on their entry form.

Application packets/entry forms are due March 1, 2018.

– NOTICE – ACPA ANNUAL CONVENTION 2018 –

Don’t miss attending the 110th Annual General Meeting of the American concrete Pipe association, March 25-27. The meeting will be held at the Rancho Bernardo Inn, a golf and spa resort near San Diego.

Don’t miss attending the 110th Annual General Meeting of the American concrete Pipe association, March 25-27. The meeting will be held at the Rancho Bernardo Inn, a golf and spa resort near San Diego.

The concrete pipe industry is celebrating 110 years of achievement and sustained success. Concrete pipe is used by municipalities and state DOTs across America to build resilient drainage infrastructure.

To Register, CLICK HERE