– Editorial –

Concrete Pipe Continues to Prove Its Superiority in Terms of Durability and Safety

By: Russell Tripp, American Concrete Pipe

The repair or replacement of infrastructure is incredibly expensive, and it typically impacts local communities with the interruption of service. In recent times, localized flooding and damaged roadways from failed pipeline systems have made news because of severely disrupted traffic. Fire damage has also caught headlines as the damage extends far beyond the damaged pipe itself to include sidewalks, roadway, gas/oil pipelines, drinking water systems and nearby structures. Building on more than 175 years of practical application, concrete pipe can help alleviate these safety and infrastructure issues.

-

Continued

Fires near concrete pipeline systems generally don’t affect structural strength or flow capacity; the two fundamental requirements of a gravity pipeline drainage or collection system. While these factors typically are not impacted near a concrete pipe, fire damage to a thermoplastic pipeline system often extends far beyond the immediate site. Thermoplastic pipe materials installed close to the surface or where there is an exposed pipeline inlet or outlet run the risk of being damaged or destroyed by fire, regardless of the use of special end treatments.

Thermoplastic pipe culvert failures have been documented where access by emergency service vehicles was blocked resulting in loss of property and threats to public health and safety.

During the 2017 Santa Rosa, California fires, underground thermoplastic drainage pipes in the North Bay fires melted and burned. Culverts were replaced and drinking water tested. In the winter of 2018, water in the neighborhood near Fountaingrove Parkway remained undrinkable because the tests found benzene, a chemical that can cause cancer[1]. A local newspaper reported that, “Since Jan. 24, when the city last released detailed test results, the city has found 58 additional instances of benzene in the drinking water in Fountaingrove. The clear majority were found within the boundaries of a 184-acre advisory zone where the city first discovered elevated levels of benzene, a chemical commonly found in plastics and gasoline that can cause cancer.”[2]

The use of HDPE and polypropylene (PP) pipe in storm-drain systems increased over the past thirty years because the purchase price was often perceived as lower than reinforced concrete and corrugated metal pipeline systems. In many jurisdictions, codes stipulate that the last few feet of a thermoplastic culvert be constructed of corrugated metal or concrete to lower the risk of structural damage in the case of fire. While such codes are helpful, they overlook the risk of fire damage to pipeline sections beyond the non-thermoplastic inlet or outfall. Such cross drains have been shown to act as paths to direct flames under roads to ignite brush and residences, thereby increasing the threat to health and safety.

The American Concrete Pipe Association published a demonstration at a concrete pipe plant showing a time lapse video of a low temperature ignition of high density polyethylene and polypropylene drainage pipe. It took only 20 minutes for the thermoplastic samples to catch fire, melt, and be reduced to a barely recognizable mass[3].

[1] Cancer-Causing Chemical Found in Some Santa Rosa Drinking Water, www.kqed.org/science/1920335/cancer-causing-chemical-detected-in-fountaingrove-drinking-water

[2] Benzene found outside Fountaingrove contamination area, The Press Democrat (http://www.pressdemocrat.com/news/8025423-181/benzene-found-outside-fountaingrove-contamination)

[3] ACPA Comparative Flammability Demonstration October 21, 2015, www.youtube.com/watch?v=FoXuyWnaJm4

Photos: courtesy of the ACPA and its members.

Concrete pipe production facilities produce one of the world’s most enduring products for storm drainage and sewage collection systems. The long-lasting performance of precast concrete drainage systems is well documented. The low temperature ignition demonstration proved the superiority of concrete pipe in terms of durability and safety in hazardous conditions.

– Article – Resilience –

Recovery From Disaster Storms Quickened With Resilient Drainage Systems

Flash Floods, or excessive rainfall in a short period that produces immediate runoff, creating flooding conditions within minutes or a few hours during or after the rainfall, are happening all too often. Such disaster storms are making news in many states that have experienced significant urban development and population growth. But, when these storms strike, rural residents and businesses also suffer significant social and economic loss. A case can be made for specifying products and materials for constructing modern drainage systems that are resilient to disaster storms.

-

Continued

Concrete pipe and precast boxes have a proven history of withstanding natural and man-made events. There is no question that precast concrete drainage systems can perform as designed for more than 100 years, as a resilient engineered structure.

Since the attack of 9/11 and devastation of hurricanes Katrina, Sandy and Harvey, lawmakers throughout the United States and Canada are creating rules, policy and passing legislation to reinforce the goal of resilient above and below ground infrastructure. The term resiliency, like its predecessor notion of sustainability, is being widely used for promoting products and services that have little to do with the original intent.

The Merriam-Webster dictionary partially explains resiliency as the ability to become strong, healthy, or successful again after something bad happens. Wikipedia says it generally means the ability to recover from some shock or disturbance.

‘Resilience theory’ was coined in the early 1970s by the Canadian ecologist C S ‘Buzz’ Holling (Emeritus Eminent Scholar and Professor in Ecological Sciences at the University of Florida) who hoped to find the hidden laws that underpin disturbance – whether out-of-the-blue, like fires or explosions, or occurring more slowly, while being similarly transformative. The use of resilience in terms of the urban environment is becoming routine.

Accepted definitions, and research by the person who developed resilience theory, strongly suggests that resilience is about bouncing back. If and when, however, disaster occurs, how well will we bounce back[1]? Applying the term to define infrastructure designed to preserve safe, healthy communities and local economies is most appropriate.

There are significant reasons for specifying concrete pipe,[2] and the specification of precast boxes for a wide range of applications is equally significant. Within this complex public and private sector marketplace, there is one constant, however, and that is the fact that concrete pipe and precast boxes used for buried infrastructure systems perform as designed for a long, long time with little unplanned maintenance.

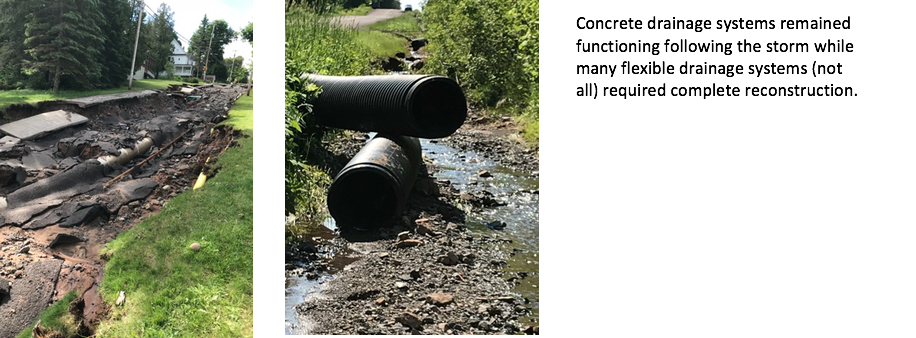

The June 15-17 flash floods that hit Houghton and Menominee counties in Upper Michigan and northwest Wisconsin testify to the need for resilient drainage systems. Although the floods caused widespread damage to many roadways, there were instances where concrete systems remained in place, allowing residents and local businesses, industries, and institutions to bounce back and recover. Even though pavements and road beds washed away, concrete sewers and culverts remained in place and functioning. Indeed, there are great costs to rebuild the roadways, but some savings were likely realized by not having to rebuild complete drainage systems where concrete was specified. Many flexible pipeline systems survived the storm, allowing speedy recovery of the transportation systems, but those that failed quickly negated any cost savings found in specifying flexible systems under local critical access roads.

No drainage system is invulnerable to the onslaught of a disaster storm. There is a wealth of knowledge, however that suggests that when drainage systems associated with major highways and local critical access roads are specified concrete, chances are greater for a faster recovery.

[1] http://citiesaregoodforyou.wordpress.com/2014/02/18/what-do-we-mean-by-resilience

[2] www.concretepipe.org/pipe-box-resources/design/14-reasons/Photos: courtesy of the ACPA and its members.

A Unique Application of Box Culverts for a Causeway

By: Scott Hofer, Director of Sales, Hancock Concrete Products LLC

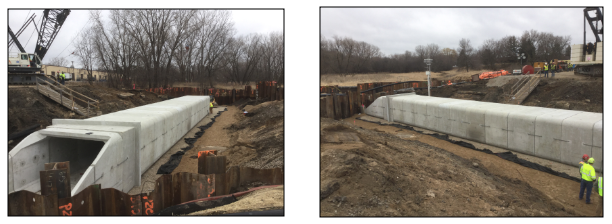

An intricate system of 22 precast concrete box culverts varying in size from 9-foot x 4-foot to 14-foot x 10-foot was applied to the design of a causeway to replace a bridge in the southwest metropolitan area of Minneapolis on U.S. Highway 169 in Hennepin County. The Minnesota Department of Transportation (MnDOT) selected the causeway design-build project because it reduced the cost of the structure along with long-term maintenance and inspection costs associated with a bridge.

An intricate system of 22 precast concrete box culverts varying in size from 9-foot x 4-foot to 14-foot x 10-foot was applied to the design of a causeway to replace a bridge in the southwest metropolitan area of Minneapolis on U.S. Highway 169 in Hennepin County. The Minnesota Department of Transportation (MnDOT) selected the causeway design-build project because it reduced the cost of the structure along with long-term maintenance and inspection costs associated with a bridge.

-

Continued

A causeway is a raised road across a low or wet ground that is supported by fill instead of piers. Nine Mile Creek Causeway is about 3/4 of a mile carrying traffic over Nine Mile Creek.

Along with a tight schedule for production of the box sections to meet the demands of project schedule, was the precise placement of concrete collars on the box sections where they were tied into the mechanically stabilized earth (MSE) walls, including two box sections that were laid on a 12-degree skew. The two skewed sections presented another challenge as the hydraulic design required a 6.5-foot rise along with its 10-foot span. Equipment modifications were necessary to produce the non-standard box section and the MnDOT Type 1 end sections.Four 110-foot long 9-foot x 9-foot precast concrete box culverts bulk headed at one end were installed as storage structures to compensate for the loss in water storage from causeway fill placement in the 100-year floodplain. In addition, sixteen 110-foot long 9-foot x 4-foot precast concrete box culverts were installed as balancing culverts to maintain equal water surface on either side of the causeway during floods. A 14-foot x 10-foot precast pedestrian box culvert was included in the causeway design for a future trail connection. Hancock Concrete Products (Cannon Falls, MN) supplied the precast boxes to Ames construction. Precast box culverts for the Nine Mile Creek project totaled over 2,400 feet.

The Nine Mile Creek box culvert, that accommodates the flow of the creek, was constructed during the winter low-flow period with a spring deadline because of environmental considerations. The alignment of the culvert was supported on a 4-foot thick load transfer platform built over three rows of steel pipe piles.

The causeway is situated on soils from the original County Road 18 roadway alignment, constructed in 1953, and its footprint extends to previously undeveloped lands. A bridge was completed immediately above the old roadway in 1976, and the route re-designated U.S. Highway 169.

Engineers conducted an extensive subsurface study of the soils and existing roadway conditions before designing the causeway, specifying all elements that would become the finished causeway comprised of concrete structures and products including the box sections used for the culverts. Work on the causeway and improvements to Highway 169 from Highway 62 to Highway 55 started January,2017 and ended in September of the same year at a cost of $64 million.

Reference: Geostrata March/April 2018

– Article – Concrete Pipe & Box Culvert –

Chilliwack Completes Critical Culvert Rehabilitation Project with Precast Concrete Pipe and Box Structures

By: Joel Shimozawa, P. Eng., Technical Marketing Engineer, The Langley Concrete Group

![]() All precast concrete products for the 2017 Culvert Rehabilitation Project for the City of Chilliwack were supplied by the primary manufacturing facility of Langley Concrete Group (LCG) in Chilliwack, British Columbia. The project consisted of replacing seven existing corrugated steel pipe (CSP) and CSP arch culverts with concrete pipe and precast concrete box structures. Several of the culverts were identified by the City as being “critical replacements” having less than 5-years of service life remaining. LCG delivered precast concrete box structures to the contractor, quickly, to enable completion of culvert construction between July 1 and September 30, the window for work on “Fisheries” -regulated streams. LCG produces dry-cast concrete products that accommodate the accelerated construction method due to high production capabilities and a controlled manufacturing environment for curing and quality control.

All precast concrete products for the 2017 Culvert Rehabilitation Project for the City of Chilliwack were supplied by the primary manufacturing facility of Langley Concrete Group (LCG) in Chilliwack, British Columbia. The project consisted of replacing seven existing corrugated steel pipe (CSP) and CSP arch culverts with concrete pipe and precast concrete box structures. Several of the culverts were identified by the City as being “critical replacements” having less than 5-years of service life remaining. LCG delivered precast concrete box structures to the contractor, quickly, to enable completion of culvert construction between July 1 and September 30, the window for work on “Fisheries” -regulated streams. LCG produces dry-cast concrete products that accommodate the accelerated construction method due to high production capabilities and a controlled manufacturing environment for curing and quality control.

-

Continued

Galvanized CSP culverts had been used in overwhelming proportions, and Chilliwack’s inspection results demonstrated that CSP had a maximum service life of 40 years, with some culverts reaching 20 years only before showing signs of failure due to corrosion. Standing water in CSP culverts causes the material to corrode at the spring line, allowing soil to infiltrate into the pipe, which compromises the soil-structure interaction required to support dead and live loads.

Galvanized CSP culverts had been used in overwhelming proportions, and Chilliwack’s inspection results demonstrated that CSP had a maximum service life of 40 years, with some culverts reaching 20 years only before showing signs of failure due to corrosion. Standing water in CSP culverts causes the material to corrode at the spring line, allowing soil to infiltrate into the pipe, which compromises the soil-structure interaction required to support dead and live loads.Since 2015, the City has used rigid infrastructure including concrete pipe and precast concrete box structures in most culvert replacements in their rehabilitation program. As the City continues to replace aging infrastructure and upgrade their drainage system to a higher standard, concrete pipe and box culverts will continue to offer a structural solution that is durable, resistant to corrosion, and designed for a service life of 100-years.

Walter’s Bulldozing was awarded the project in June 2017. In areas of critical habitat that included the Oregon Spotted Frog and the Salish Sucker, additional site enhancements such as the installation Coho gravel inside the culverts were completed.

The Langley Concrete Group has extensive experience working with contractors, municipalities, and the province in rehabilitating critical infrastructure, especially Chilliwack where LCG’s robotic production facility is located. LCG is actively involved with community initiatives, and with over 60 employees from the municipality, there was a great sense of pride in producing and supplying quality, structural, precast concrete products that can be relied upon for generations.

Project Details

Project Name: 2017 Culvert Rehabilitation / Tender No. 2017-10

Location: Various locations in Chilliwack

Project Manager: Kyle St. Amour, Drainage Technician, City of Chilliwack

Engineering Design Consultants: McElhanney Consulting Services Ltd. & ISL Engineering and Land Services

Contractor: Walter’s BulldozingPhotos: courtesy of the ACPA and its members.

– Article – Box Culvert –

Richmond Raceway Pedestrian Tunnel Constructed with Precast Concrete Box Segments

By: Whitney West, Oldcastle Precast

Innovative best describes the precast concrete pedestrian tunnel constructed for International Speedway Corporation’s Richmond Raceway Reimagined project. The tunnel is wider, providing fans with more comfortable access to the updated infield, and includes an elevator for added convenience and Americans with Disabilities Act (ADA) accessibility. Oldcastle supplied 49 (10-foot x 10-foot) precast concrete box segments for the 415-foot tunnel. Three segments were designed to elevate the walkway and match the grade of the concourse.

-

Continued

A portion of the racetrack was excavated for the tunnel crossing alignment and installation of the box segments. Assembly of the sections required 6,506 cubic yards of concrete, 220,326 square feet of slab and 256,000 pounds of rebar. The structure weighs 1,100 tons.

Precast concrete box sections can be used in countless applications. They are installed quickly and provide the highest level of strength and durability. In addition, precast concrete box segments are less dependent on backfill, require little to no maintenance, can withstand aggressive compacting, and are produced locally. Precast concrete pedestrian tunnel segments provided Richmond Raceway with an efficiently-constructed structure that was installed in 5 days, saving time and money.

Construction of the Richmond Raceway is expected to be completed by September 2018, in time for the playoff races for the Monster Energy NASCAR Cup and XFINITY Series.

Project Team

Project Team

General Contractor: Barton Malow

Architect of Record: DLR Group

Civil Engineer: HG Design Studio (Richmond)

Site Contractor: Alpine Construction Corporation

Precast Producer: Oldcastle Precast (Fredericksburg)

– Article – Box Culvert –

Oldcastle Supplying Precast Box Sections for Culverts on State Route 58 Kramer Junction Expressway Project

By: Doug McLaughlin, California Director, California Precast Concrete Pipe Association

![]() Oldcastle is supplying precast concrete box section to be used for the construction of culverts on the widening of State Route 58 (SR-58), in the County of San Bernardino, California, near the Kern County line to 7.5 miles east of (E/O) US Highway 395. The Caltrans Kramer Junction Project closes the gap in the four-lane expressway system for route continuity, accommodates increased volumes of oversized vehicles, and provide a grade separation for a railroad crossing.

Oldcastle is supplying precast concrete box section to be used for the construction of culverts on the widening of State Route 58 (SR-58), in the County of San Bernardino, California, near the Kern County line to 7.5 miles east of (E/O) US Highway 395. The Caltrans Kramer Junction Project closes the gap in the four-lane expressway system for route continuity, accommodates increased volumes of oversized vehicles, and provide a grade separation for a railroad crossing.

-

Continued

A unique use of the projects culverts is to mitigate disruption to animal movement. Two oversized culverts east and west of US-395 were installed for the passage of the threatened and endangered desert tortoise and Mojave ground squirrel.

A unique use of the projects culverts is to mitigate disruption to animal movement. Two oversized culverts east and west of US-395 were installed for the passage of the threatened and endangered desert tortoise and Mojave ground squirrel.The sole contractor for the project is Kiewit Infrastructure West Co. with experience managing highway and bridge work in California. By April 18, 2018, Oldcastle had delivered 12-foot x 7-foot gasketed box sections. Each section weighed approximately 39,000 lb. Oldcastle’s Dave Reneson was on site to assist the contractor with recommended installation techniques and proper application of the gaskets.

Photos: courtesy of the ACPA and its members.

– Article – AASHTO –

ACPA a Sponsor of the 2018 AASHTO TRAC Bridge Competition

AASHTO’s Transportation and Civil Engineering (TRAC) and RIDES (Roadways In Developing Elementary Students) programs are designed for students in separate age categories: grades 7-8, 9-10, and 11-12. Eighteen teams from Michigan, Virginia, Mississippi, Florida, New Mexico, California, and Maryland participated in the 2018 competition. Team members were involved in one of AASHTO’s educational outreach programs (TRAC or RIDES). The competition’s goal is to develop a bridge that will carry as much weight as possible while weighing as little as possible.

AASHTO’s Transportation and Civil Engineering (TRAC) and RIDES (Roadways In Developing Elementary Students) programs are designed for students in separate age categories: grades 7-8, 9-10, and 11-12. Eighteen teams from Michigan, Virginia, Mississippi, Florida, New Mexico, California, and Maryland participated in the 2018 competition. Team members were involved in one of AASHTO’s educational outreach programs (TRAC or RIDES). The competition’s goal is to develop a bridge that will carry as much weight as possible while weighing as little as possible.

-

Continued

Teams of three were chosen to attend the TRAC Bridge Finals at the AASHTO Spring Meeting, May 21 – 24 in Franklin, Tennessee and present their designs to a panel of judges comprised of various AASHTO members and sponsors. ACPA was one of the sponsors. Design drawings were 10% of the total score, an oral presentation 30%, and performance goals and stability of construction 60%. The First Place Team was awarded $1,200, the Second Place Team $900, and Third Place Team $600.

Michigan teams took first place honors in the three age categories and secured seven of the nine top spots.

2018 Annual TRAC Bridge Challenge Winners

11-12th Grade Division

First: Negaunee High School – Bridge Builders, Negaunee, Michigan

Second: LISD Tech Center – Land Linkers, Adrian, Michigan

Third: Schoolcraft High School – The Internationals, Schoolcraft, Michigan9-10th Grade Division

First: Kat Homeschool – Millennium A.R.K. Designers, Portage, Michigan

Second: Henrico High School – Setu Builders, Henrico, Virginia

Third: Pembrook Pines School – Jags Team B, Fort Lauderdale, Florida7-8th Grade Division

First: Meads Mill Middle School – Trussworthy, Northville, Michigan

Second: Portage Central Middle School – CNM, Portage, Michigan

Third: Portage Central Middle School – Bridge-it, Portage, MichiganTRAC is a hands-on education program designed for integration into science, math, and social science classes with the goal of encouraging children to pursue engineering and other science-related fields. The bridge challenge is part of the Michigan Department of Transportation’s (MDOT) TRAC program curriculum. MDOT has been offering the TRAC program to Michigan schools since 2004.

Photos: courtesy of the ACPA and its members.

– Concrete Pipe Week –

Concrete Pipe Week 2018 is a Time to Celebrate

Celebrate Concrete Pipe Week by requesting state Governors to recognize Concrete Pipe Week across America with proclamations from their states.

Thirty states representing nearly 75 percent of the U.S. population issued proclamations recognizing Concrete Pipe Week in 2017. In 2016, 26 states representing 64 percent of the U.S. population issued proclamations. The event launched in 2015 generated proclamations in 11 states that year, accounting for about one-quarter of the U.S. population. It is clear that Concrete Pipe Week has traction in industry and government. Let’s work to make Concrete Pipe Week 2018 the best ever.

During Concrete Pipe Week, producers host plant tours, employee appreciation events, and engage federal, state and local elected officials in discussions about product quality, performance and resilience as they relate to storm and sanitary sewer infrastructure, culverts and small precast bridges. Proclamations underscore the indisputable contributions that producers, their team members and their customers make to the economy and environment.

Concrete Pipe Week recognizes the significance that the reinforced concrete pipe and precast industry has in community quality of life, and affirms the contributions of the concrete pipe and precast industry to each state. Concrete Pipe Week is a time to recognize the contributions of ACPA’s associate members; steel producers, form producers, casting producers, the trucking industry, sand and rock producers, cement producers, contractors, academia, and everyone associated with the buried infrastructure industry and the products this industry requires.

For answers to questions about the proclamation process or need assistance in coordinating your activities contact Walt Catlett.

– Project Achievement Award –

Win Recognition of Any AASHTO Member Agency with a Project Achievement Award

Any member agency of AASHTO may enter the 2019 Project Achievement Award. Agencies and ACPA members may submit projects jointly or separately. ACPA members submitting projects separately must obtain the signature of the responsible agency on their entry form.

Any member agency of AASHTO may enter the 2019 Project Achievement Award. Agencies and ACPA members may submit projects jointly or separately. ACPA members submitting projects separately must obtain the signature of the responsible agency on their entry form.

The annual award was established to recognize agencies which have demonstrated creative and innovative accomplishments through projects that have been designed utilizing precast concrete pipe or boxes.

Projects must have been completed and in use between January 1, 2013 and December 31, 2018. Application packets/entry forms are due March 1, 2019. The winner is notified on April 15, 2019 and the award presented during the AASHTO Bridge and Structures Subcommittee meeting in Alabama in June.

Pictures submitted with all project applications will be incorporated into a PowerPoint slide show at the AASHTO Awards Ceremony, and submittals will receive recognition in the Fall Issue of Concrete Pipe News. The Award Winner will be invited to accept the award and speak during the Awards Ceremony.

To enter a project, CLICK HERE.

Direct questions to:

Josh Beakley, P.E., ACPA

Roman Selig, Hamilton Kent

Jeff Hite, Rinker Materials